LGS CREATING GLS

BOLTED GLASS LINED STEEL TANKS

LIQUID GRAIN STORAGE PROJECTS

LIQUID GRAIN STORAGE PROJECTS

LIQUID GRAIN STORAGE PROJECTS

LIQUID GRAIN STORAGE PROJECTS

LIQUID GRAIN STORAGE PROJECTS

LIQUID GRAIN STORAGE PROJECTS

LIQUID GRAIN STORAGE PROJECTS

LIQUID GRAIN STORAGE PROJECTS

Our Products

Clients Our Team Has Worked With

Our Team's Impact in Numbers

1130

Projects Completed

51

Team Size

21

Countries Served

1030

Happy Clients

Our Recent News & Blog

10

Jul

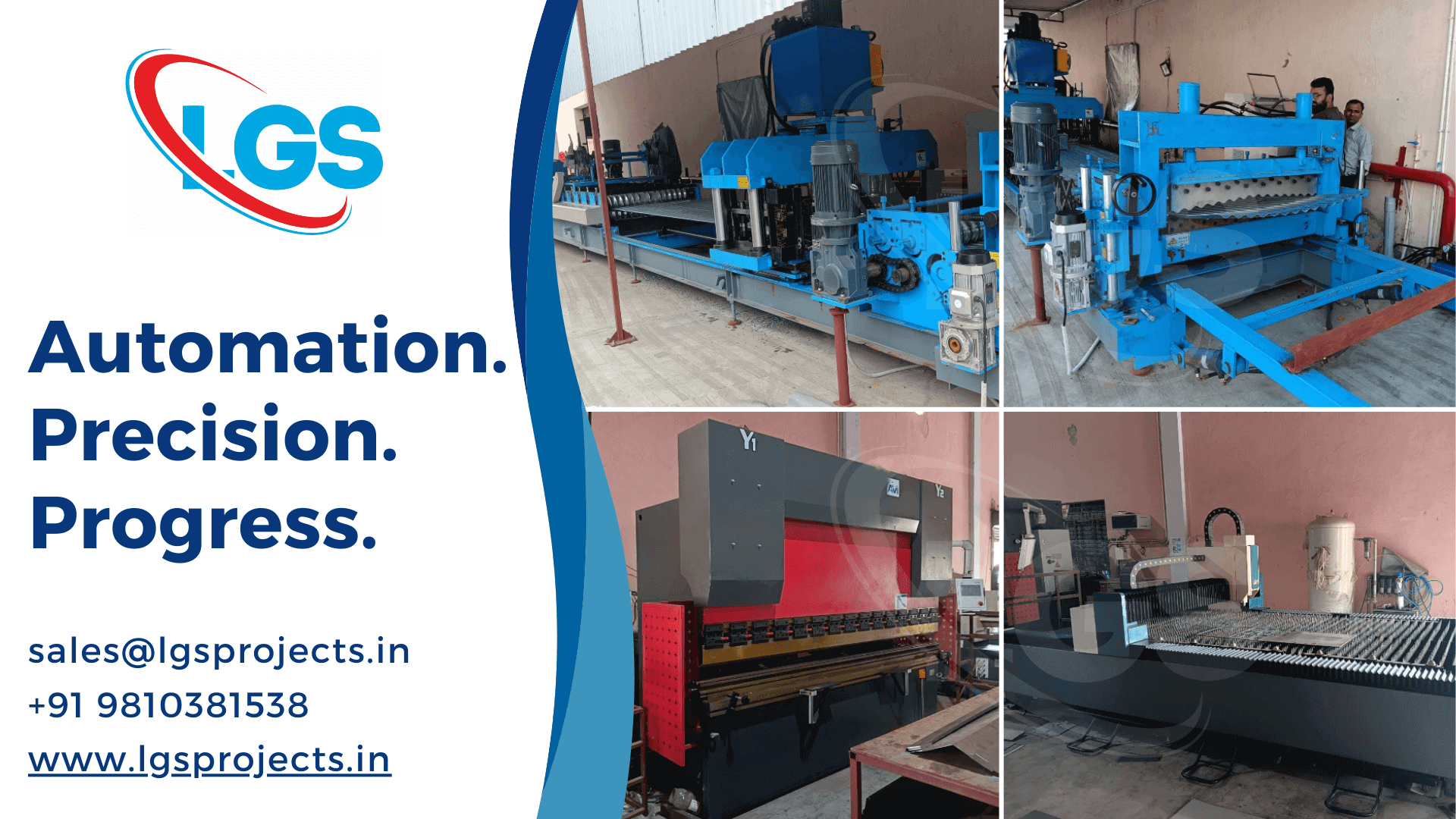

LGS PROJECTS PRIVATE LIMITED

India’s First Fully Automatic Sinusoidal Sheet Profiling Machine

At LGS Projects Pvt. Ltd. we are revolutionizing steel tank and silo manufacturing in India. We are proud to unveil a breakthrough that sets new benchmarks in industrial automation: India’s first fully automatic sinusoidal sheet profiling machine.This milestone reflects our …

14

Apr

LGS PROJECTS PRIVATE LIMITED

Effluent Treatment Plant: Zincalume Steel Tanks

In the critical infrastructure of modern Effluent Treatment Plants (ETPs), the selection of durable and cost-effective storage solutions is paramount. LGS PROJECTS specializes in providing high-performance bolted Zincalume steel tanks that can be engineered specifically for the rigorous demands of …

27

Mar

LGS PROJECTS PRIVATE LIMITED

Flat Bottom Silo

Flat bottom silos are the ideal choice for bulk and long-term dry storage, particularly for capacities exceeding 500 MT. Their design, incorporating advanced technology, ensures they can withstand the rigors of various material storage applications. Our silos are constructed using …

17

Mar

LGS PROJECTS PRIVATE LIMITED

Hopper Bottom Silo

Hopper bottom silos from LGS Projects offer the perfect solution for industries ranging from agriculture and food processing to mining and chemical manufacturing. These silos are engineered for gravity discharge, streamlining your operations and minimizing material handling costs. Let's dive …

28

Feb

LGS PROJECTS PRIVATE LIMITED

Hopper Bottom Silo vs. Flat Bottom Silo: Understanding the Differences

When considering grain storage solutions, two prominent types of silos come to mind: Hopper Bottom Silos and Flat Bottom Silos. Each type has its unique design, advantages, and applications, making them suitable for different operational needs. Understanding these differences can …