NEWS

INDUSTRY INSIGHTSIndia’s First Fully Automatic Sinusoidal Sheet Profiling Machine

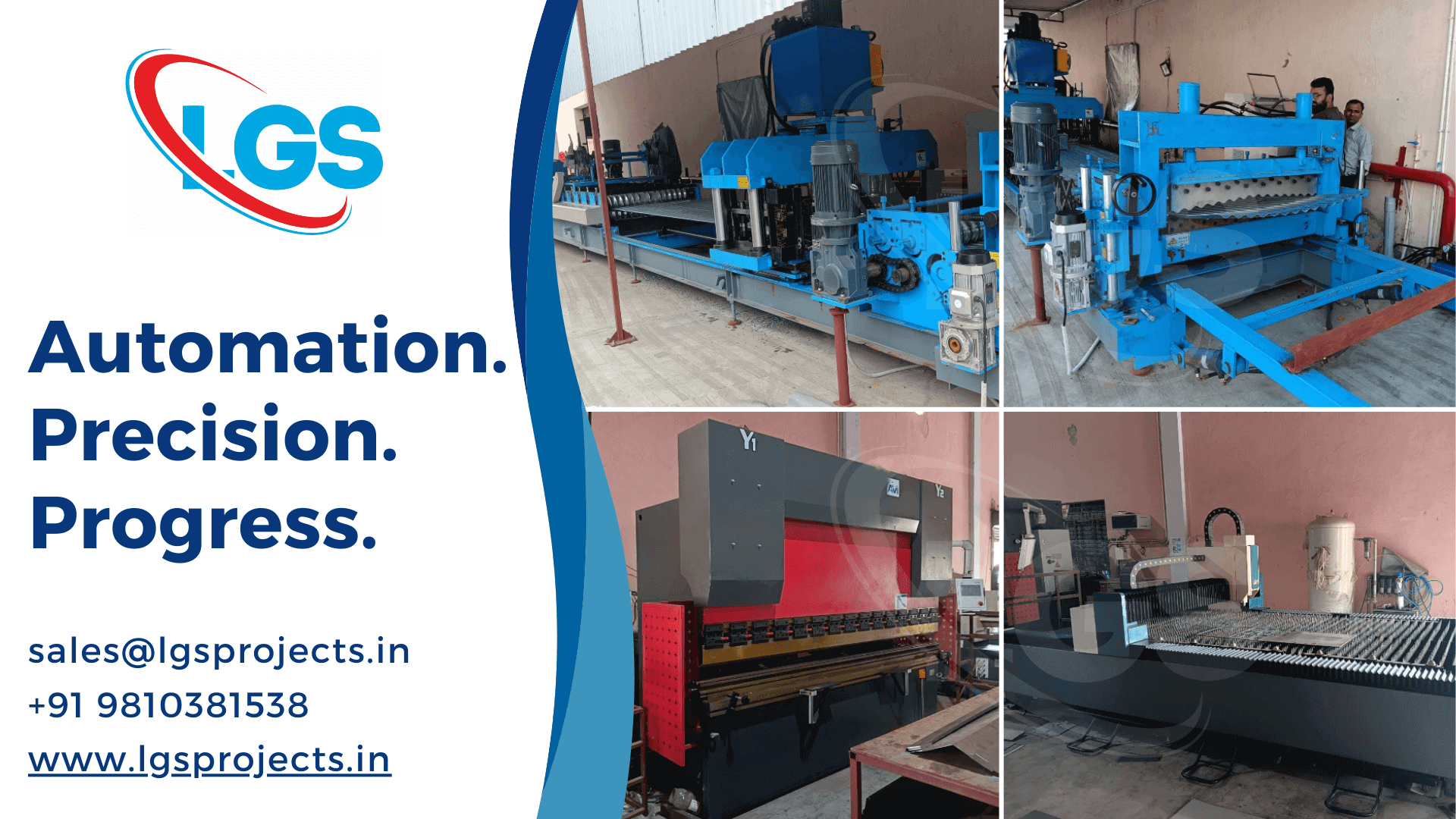

At LGS Projects Pvt. Ltd. we are revolutionizing steel tank and silo manufacturing in India. We are proud to unveil a breakthrough that sets new benchmarks in industrial automation: India’s first fully automatic sinusoidal sheet profiling machine.

This milestone reflects our commitment to advancing manufacturing excellence, precision engineering, and industrial automation, enabling us to serve diverse sectors with world-class storage solutions, including Zincalume steel tanks, Glass Fused Steel tanks, silos, and industrial storage systems.

What Makes This Innovation Unique?

We're first in India to have this fully automatic sinusoidal sheet profiling machine which is designed to perform multiple sequential operations in a single smooth process - all with minimal human intervention.

Key Features Include:

-

Automatic De-coiling: Efficient handling of metal coils with zero manual effort.

-

High-Precision Profiling: Sinusoidal sheets are produced with unmatched accuracy.

-

On-the-fly Punching: Integrated punching system for precise design adjustments.

-

Sheet Curving: Achieving flawless curves essential for tank and silo construction.

-

Automated Cutting: Precision cutting ensures zero waste and exact dimensions.

This machine eliminates the need for multiple machines, reducing the number of operators and minimizing handling. As a result, it offers a more resource-efficient, safe, and scalable solution.

The Impact on Our Clients

-

Superior Product Quality: Built with cutting-edge machinery and precision engineering.

-

Faster Delivery Cycles: Automation accelerates production speed.

-

Cost Efficiency: Reduces waste and improves overall process efficiency.

Competitive Advantage: With faster turnaround times, stringent quality control, and adherence to global manufacturing standards, our products are of the highest quality, delivered on time, every time.

Frequently Asked Questions (FAQs)

Q1: What industries benefit from this innovation?

Industries like agriculture, water management, chemical processing, food & beverage, and municipal corporations will benefit from faster, more accurate, and durable tank and silo manufacturing.

Q2: How does automation reduce costs for clients?

Automation minimizes material wastage, saves labor costs, and reduces production time, making projects more affordable without compromising quality.

Q3: Why sinusoidal profiling matters in tanks and silos?

Sinusoidal sheets improve structural strength, durability, and resistance to environmental stress, making them ideal for creating long-lasting storage tanks and silos.

The Future of Industrial Tank and Silo Production

By merging automation, precision engineering, and sustainable practices, LGS Projects is leading the way in the future of industrial tank and silo production. This is not the end — it’s just the beginning of many innovations we aim to bring to the industry.

Our Smart Manufacturing Facility

From CNC machines to laser cutting, from curated furnace technology to our brand-new sinusoidal sheet profiling machine, our facility now exemplifies what many aspire to: a smart factory that thinks and works even smarter.

We don’t just build tanks, silos, and steel structures -- we’re engineering the future of manufacturing innovation.

📞 Contact us today to schedule a plant tour and see manufacturing magic in action!